Industry: Plastic Manufacturing

Client: Plastix AB, Sweden

Concept & Problem Statement

Modern plastic factories often operate with outdated or disconnected systems for managing employees, machines, production, and inventory. This creates inefficiencies, miscommunication, and lost data. Plastix AB needed a centralized digital platform to streamline operations, empower workers, and give administrators clear oversight — all through a clean, mobile-friendly UX.

Research & Process

I began by defining the two key user types:

-

Administrators – responsible for shift planning, machine tracking, reports, and stock.

-

Employees – on the floor daily, needing clarity on their shifts, assigned tasks, and machines.

User Research Steps:

-

Conducted 1:1 interviews with factory managers and line workers.

-

Created journey maps.

-

Reviewed pain points in traditional Excel/whiteboard-based systems.

-

Benchmarked other B2B factory tools for UX inspiration.

Core Challenges Identified:

-

Lack of real-time visibility into daily tasks and machine usage.

-

Confusing shift and machine assignment methods.

-

Fragmented reporting and inventory systems.

Key UX Goals

-

For Admins: Centralized control with real-time data, scheduling ease, and production insights.

-

For Employees: A straightforward mobile interface to view their tasks, machines, and timesheets.

UI Overview: Admin Side

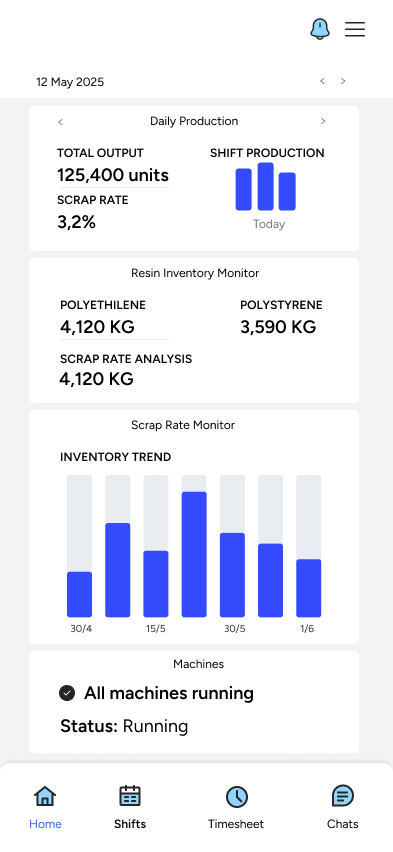

Dashboard

- Overview of shift coverage, operational status, alerts, and machine performance.

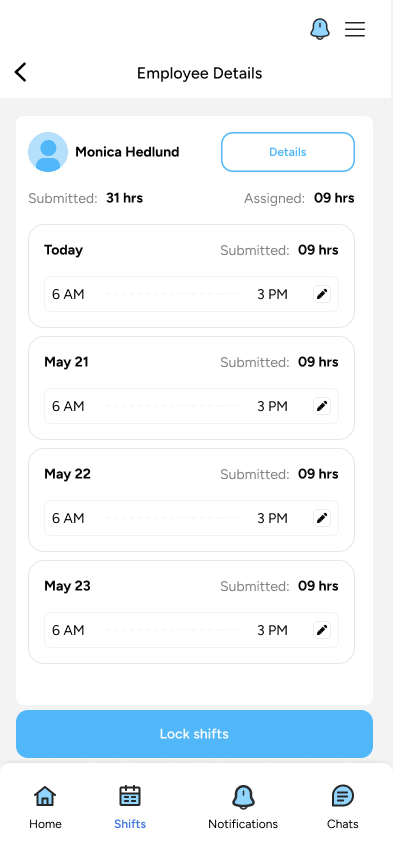

2. Employee Management

-

Add, remove, or update workers.

-

View employee profiles, roles, and current shift status.

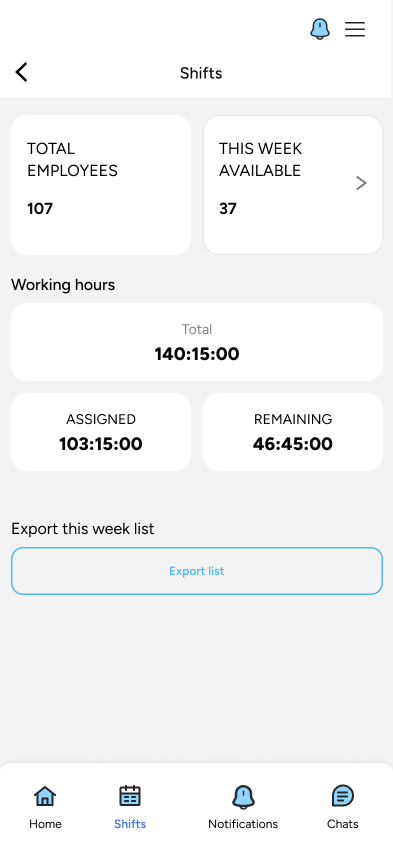

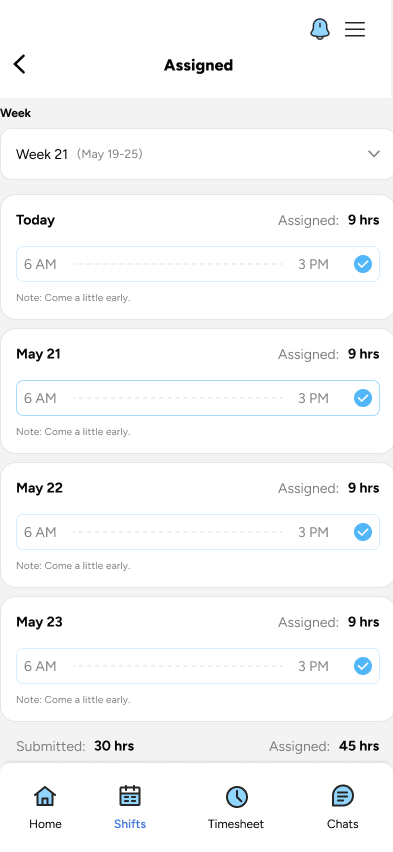

3. Shift Planner

-

Calendar-based interface for assigning roles and machines.

-

Visual indicators for unfilled shifts.

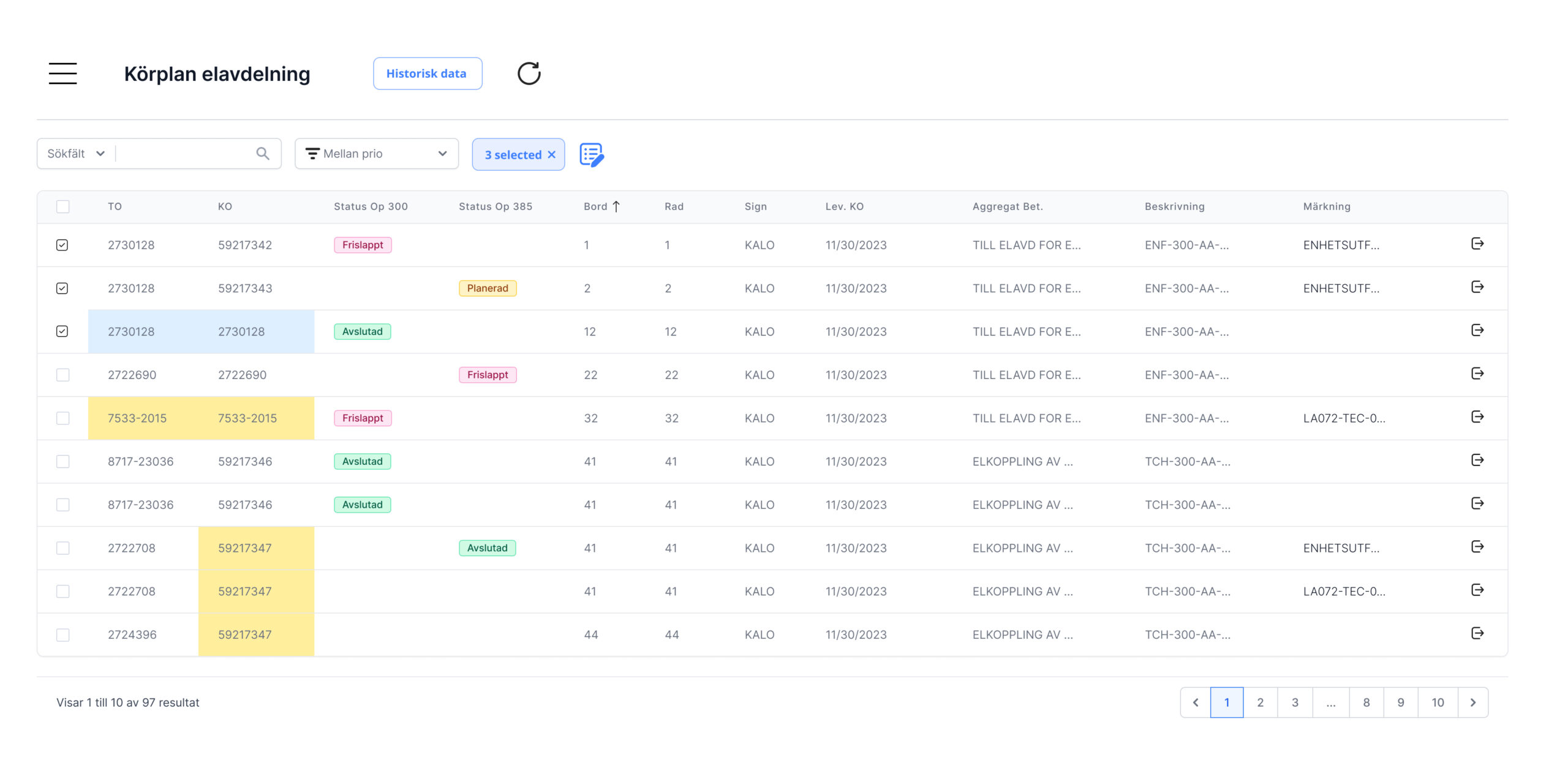

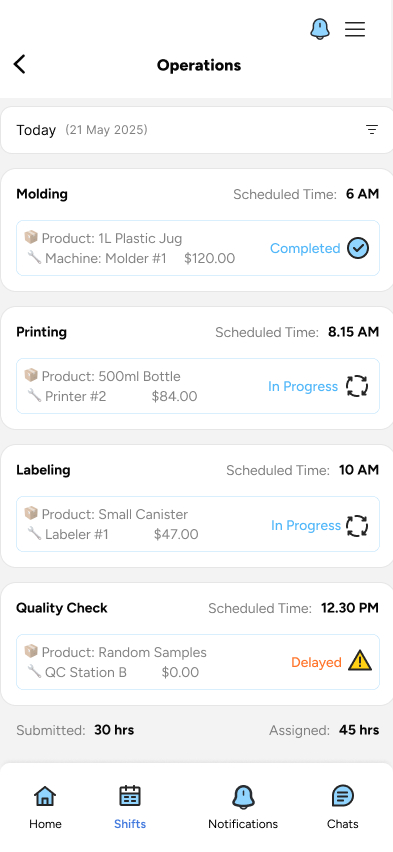

4. Operations Hub

-

Combined module for:

-

Operations (molding, printing, etc.)

-

Inventory status (in stock, committed, excess)

-

Timesheet verification

-

Reports (output, downtime, cost)

-

5. Machine Management

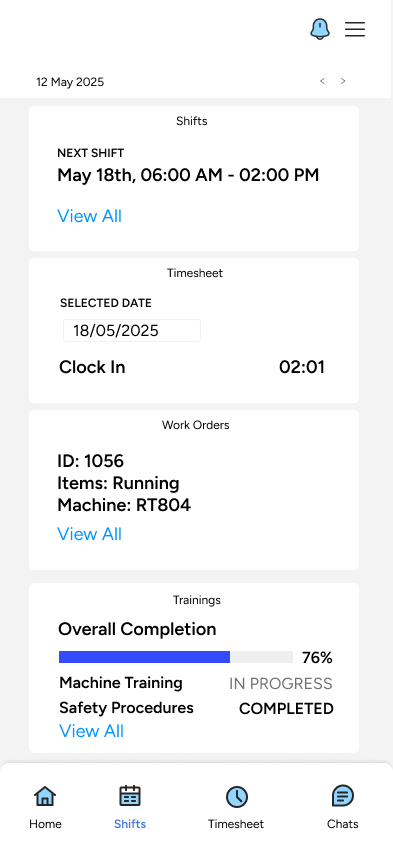

UI Overview: Employee Side

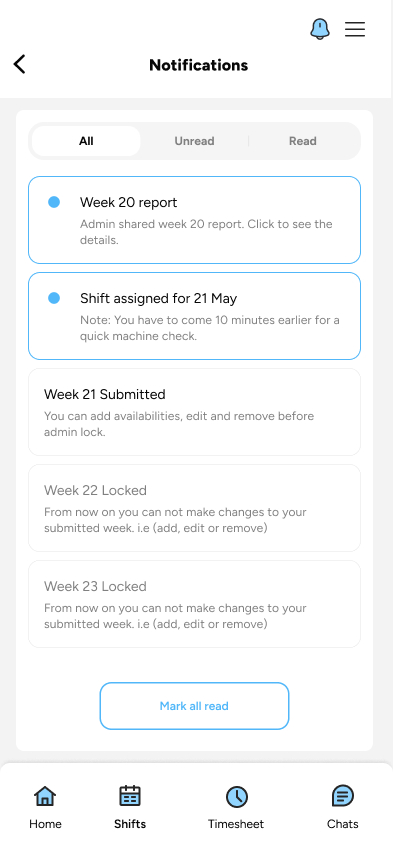

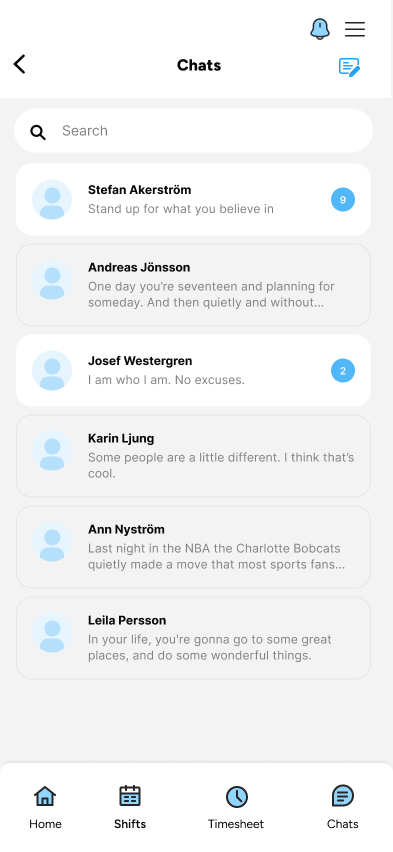

These screens are designed for workers using the system on mobile devices.

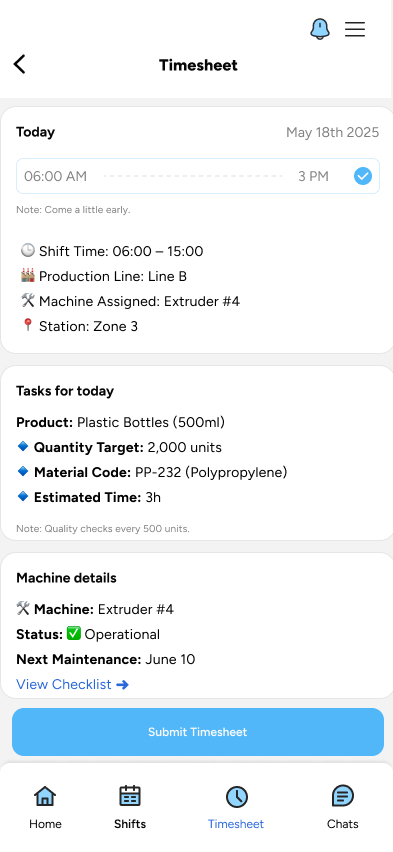

1. Timesheet

-

View daily schedule, assigned operations, machine, output quantity, and targets.

2. Task View

-

Daily checklist of tasks with the ability to mark as complete.

-

Expanded view includes machine info, materials needed, and output expectations.

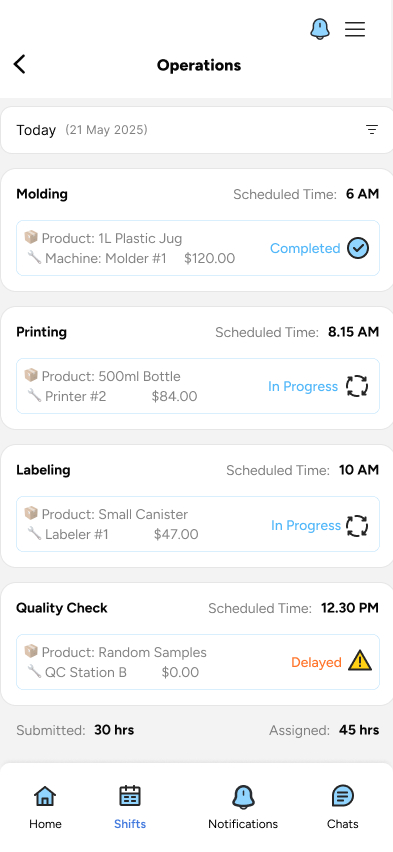

3. Operation Details

-

Tapping on a daily operation expands to reveal:

-

Task type (e.g., Printing)

-

Assigned machine

-

Quantity to produce

-

Time allocated

-

Notes from supervisors

-

4. Inventory Overview

-

Shows materials available at the workstation.

-

Alerts if stock is running low or delayed.

Outcome

The solution brings clarity, accountability, and operational efficiency to factory life, empowering both managers and workers to perform better. The flexible structure also allows this system to be adapted to other manufacturing industries.